رازداری کا بیان: آپ کی رازداری ہمارے لئے بہت اہم ہے۔ ہماری کمپنی وعدہ کرتی ہے کہ آپ کی واضح اجازتوں کے ساتھ آپ کی ذاتی معلومات کو کسی بھی ایکسپانی سے ظاہر نہ کریں۔

ماڈل نمبر.: AW()

برانڈ: Amrta or OEM

پیکیجنگ: Standard Package for Export Transport

پیداوری: 5000SETS/Year

نقل و حمل: Ocean,Air

نکالنے کا مقام: China

سپلائی کی قابلیت: 400PCS / Month

ایچ ایس کوڈ: 8418612090

پورٹ: Qingdao,Shandong,China

ادائیگی کی قسم: L/C,T/T

انکوٹرم: FOB,CFR,CIF

Recirculating refrigerated fluid water chiller is used in the wine and microbrew industry to control temperature in the production of fine table wines and craft beer. To create these high quality wines and beer the proper temperature must be maintained during the entire production process. The industrial cooling system has specific needs that require high harvest cooling capabilities, tight temperature control, and large capacities at low stabilization temperatures. Amrta air conditioning offer several complete lines of high quality recirculating refrigerated fluid brewery water chiller for the wine and beer making industry.

Why this choice?

● Very high efficiency with R410A

● Very low noise operation

● R410A scroll compressors

● Advanced control

● Unit with pump and optional buffer tank

● Very compact for outdoor or indoor installation

Characteristics

The master module can work independently or together with up to 16 slave modules.

Units with V type heat exchanger: panels, frame and base are made from galvanized steel protected with polyester powder painting to ensure total resistance to atmospheric agents.

3-phase scroll type compressor, with builtin thermal overload cut-out and crankcase heater, mounted on rubber vibration dampers.

External rotor type axial fans, equipped with three phase direct drive motors, low noise 8 poles, protection level IP54, provided with a protective outlet grille.

Evaporator built with high efficiency shell and tube type heat exchanger, factory insulated with flexible close cell material.

Condenser built with seamless copper tubes mechanically expanded into blue hydrophilic aluminum fins.

Refrigerant circuit complete with charge valves, filter drier, sight glass, gas-liquid separator, thermostatic expansion valve, high & low pressure switch. The heat pump system unit is completed also with 4-way valve, liquid receiver and one way valve.

Hydraulic circuit built with galvanized pipe, complete with water discharge connection for tube in tube heat exchanger and flange type hydraulic connectors in two directions easy for connections from both sides of the units.

Electric panel consist of:

Compressor contactor, fan motor contactor, compressor protection breaker, fan protection breaker, phase sequence relay and microprocessor with function display (display only for master/packaged unit)

Automatic operation dramatically reducing maintenance cost thanks to reliable microprocessor system.

Optional

Paddle flow switch;

Metallic filter for hydraulic circuit;

Water pump;

Rubber antivibration mounting;

Heat recovery functions.

Technical Data

| Model AW | 60 | 100 | 130 | 200 | 260 | ||

| Cooling capacity* | kW | 65 | 97.5 | 130 | 195 | 260 | |

| Cooling power input | kW | 20.8 | 31.4 | 42.1 | 63.6 | 84.2 | |

| Heating capacity** | kW | 68 | 102 | 136 | 204 | 272 | |

| Heating power input | kW | 20.2 | 30.6 | 41 | 61.2 | 82 | |

| Max Input Power | kW | 24 | 35.7 | 47.7 | 71.4 | 95.4 | |

| Max Input current | A | 50 | 74 | 97 | 148 | 194 | |

| Cooling Running Current | A | 46 | 68 | 89 | 136 | 178 | |

| Start-Up Current | A | 167 | 187 | 206 | 374 | 412 | |

| Compressor | |||||||

| Power supply | / | 380/3/50 | |||||

| Brand/Type | / | Daikin/Scroll | |||||

| Refrigerant | / | R410a | |||||

| Qty/refrigerant circuit | Nr. | 2 | 3 | 4 | 6 | 8 | |

| Cooling power input* | kW | 2*9.4 | 3*9.63 | 4*9.77 | 6*9.63 | 8*9.77 | |

| Heating power input** | kW | 2*9.1 | 3*9.36 | 4*9.5 | 6*9.36 | 8*9.5 | |

| Energy adjustment | % | 0-25-50-75-100 | |||||

| Axial fan | |||||||

| Quantity | Nr. | 2 | 2 | 2 | 4 | 4 | |

| Power input | kW | 2 | 2.5 | 3 | 5 | 6 | |

| Airflow | m3/h | 24000 | 36000 | 48000 | 72000 | 96000 | |

| Evaporator | |||||||

| Type | / | Shell and tube heat exchanger | |||||

| Water flow when cooling | m3/h | 11.2 | 16.8 | 22.4 | 33.6 | 44.8 | |

| Water flow when heating | m3/h | 11.7 | 17.6 | 23.4 | 35.1 | 46.8 | |

| Water side pressure drop *** | kPa | 46 | 52 | 55 | 52 | 55 | |

| Water connection size | DN | 50 |

50 |

65 | 2x50 | 2x65 | |

| Noise level*** | dB(A) | 70 | 72 | 72 | 74 | 75 | |

| Dimensions | |||||||

| V type coil | Length | mm | 2000 | 2207 | 2207 | 2207 | 2207 |

| Width | mm | 1060 | 1300 | 1300 | 2207 | 2207 | |

| Height | mm | 1957 | 2076 | 2076 | 2096 | 2096 | |

| Net weight | kg | 620 | 1060 | 1120 | 2160 | 2280 | |

| Working weight | kg | 635 | 1090 | 1155 | 2220 | 2350 | |

**** Sound pressure measured at a distance of 1 m and a height of 1.5 m above the ground in a dear field.

Why Choose AMRTA?

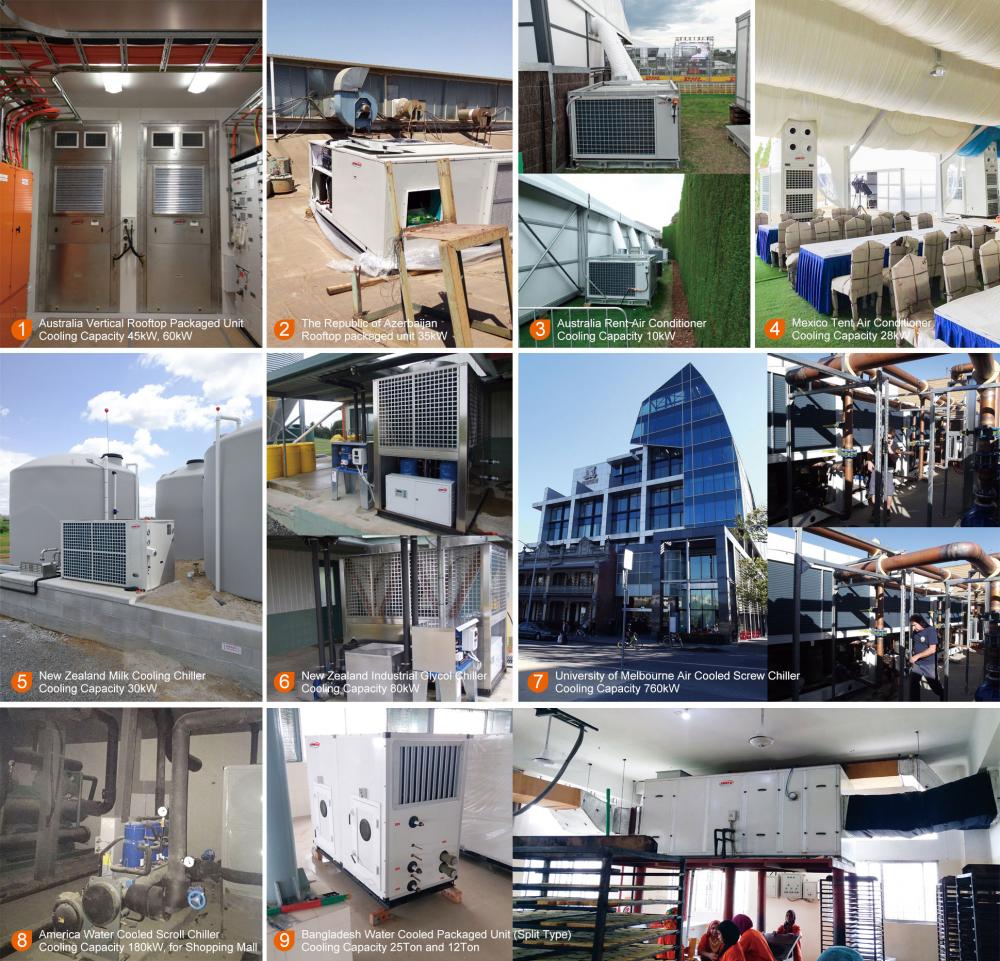

Project

Ordering Process

مصنوعات کی اقسام : واٹر چلر۔ > بریوری واٹر چلر۔

رازداری کا بیان: آپ کی رازداری ہمارے لئے بہت اہم ہے۔ ہماری کمپنی وعدہ کرتی ہے کہ آپ کی واضح اجازتوں کے ساتھ آپ کی ذاتی معلومات کو کسی بھی ایکسپانی سے ظاہر نہ کریں۔

مزید معلومات کو پُر کریں تاکہ آپ کے ساتھ تیزی سے رابطہ ہوسکے

رازداری کا بیان: آپ کی رازداری ہمارے لئے بہت اہم ہے۔ ہماری کمپنی وعدہ کرتی ہے کہ آپ کی واضح اجازتوں کے ساتھ آپ کی ذاتی معلومات کو کسی بھی ایکسپانی سے ظاہر نہ کریں۔